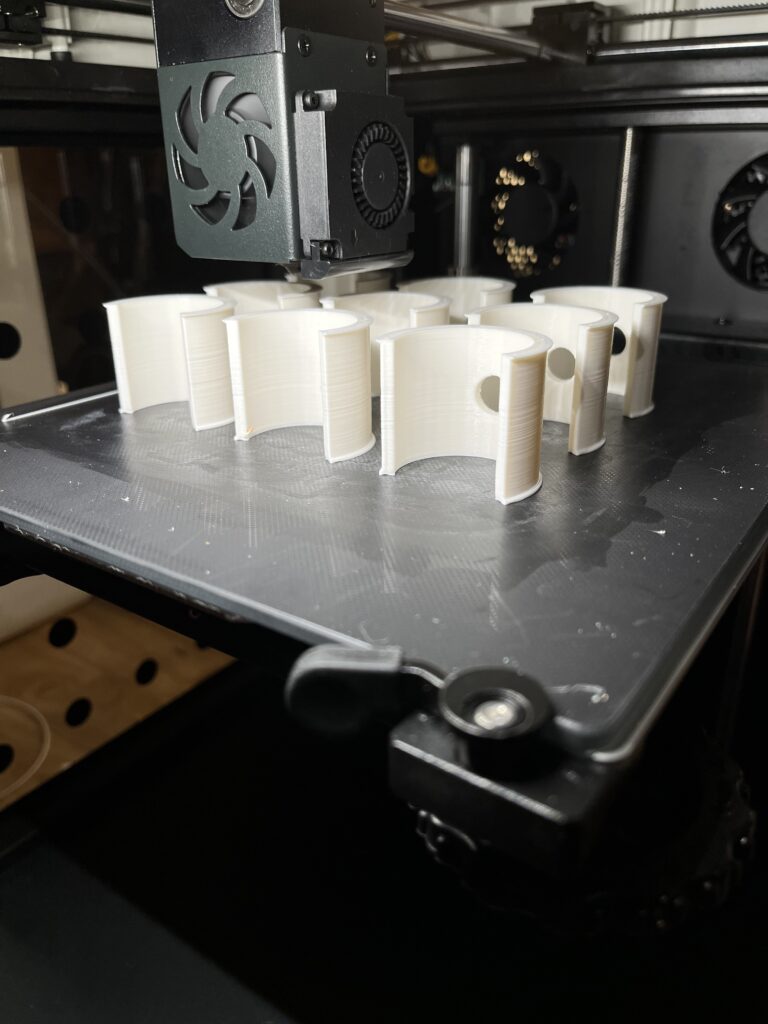

At JEMSMART, we are using 3D printing technology to speed up product development and to bring new products to market in a matter of days instead of the several weeks that it would normally take with standard injection mold tooling. This also allows us to minimize production costs for low volume products that would otherwise not be viable to bring to market due to high tooling costs. For the Potty Sniffer system, 3D printed components have been proven in testing to be a suitable alternative to regular injection molded plastic parts for functionality and long-term durability. We currently have (4) 3D printing machines that are capable of running around the clock producing ABS components for both prototype and production.