You never saw this…

Why are we showing you this…?

This will definitely void the warranty…

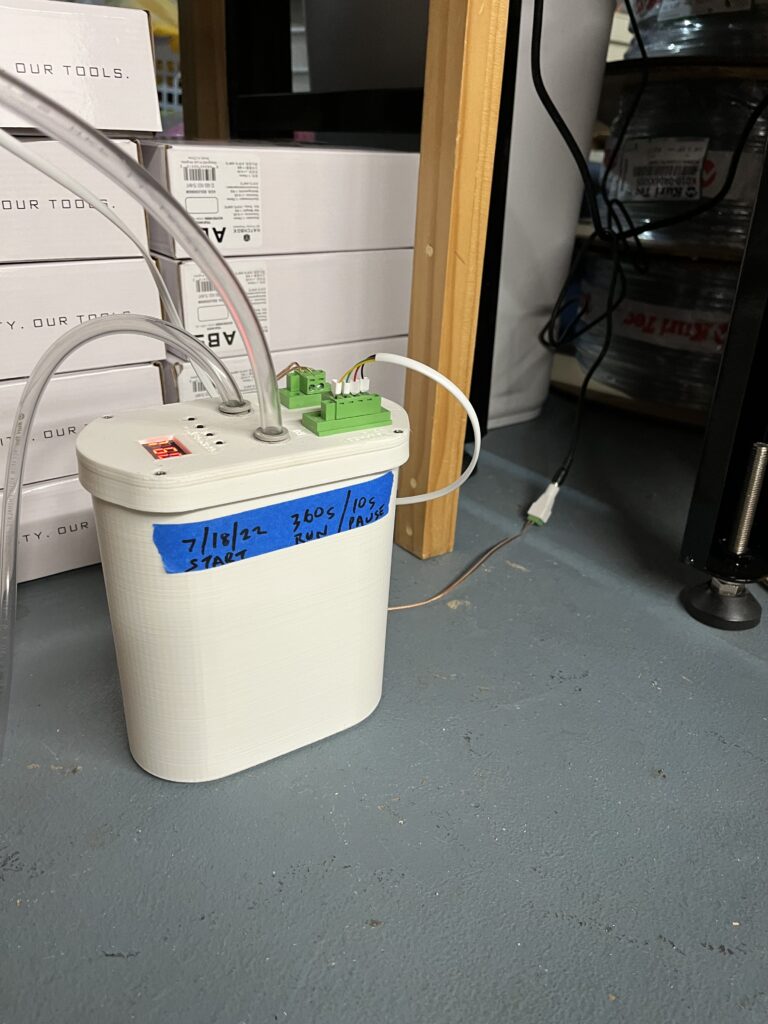

At JEMSMART, we have been running a prototype Sniffer pump on a long-term durability test cycle since the middle of July 2022 in order to determine the operating life of the pump. The test unit has been running a 6 minute ON / 10 seconds OFF repeating cycle continuously since the start without issues as of the date of this post. This works out to about 140 days (3,400 hrs) of continuous operation and counting.

Since the durability test pump was needing to run continuously, we decided to put it to work for us by using it as a fume ventilation system for our small fleet of 3D printers. When 3D printing ABS plastic, a heated machine bed and enclosure is normally required to reduce warping, promote adhesion, and to achieve the best part quality. During the process of melting 3D print filament, molten plastic fumes are produced as a byproduct and normally requires ventilation when multiple machines are being run at the same time in a production environment. There is some debate whether these fumes are actually toxic, but they definitely do smell bad and is not something we would want to breathe in constantly if it could be avoided. Overall, our setup is working very well, and the heated air being sniffed by the pump was an extra stress factor that would help simulate running the pump in a hot environment. We are also benefitting from significant energy savings through wasted heating and cooling costs that would have been incurred for a traditional room fan ventilation system. So this has been a total win-win-win scenario for us.

This little tidbit of JEMSMART trivia got shared as we discussed our product development and testing progress with some of our friends and associates and, of course, we received a number of requests for more information about our 3D printing setup.

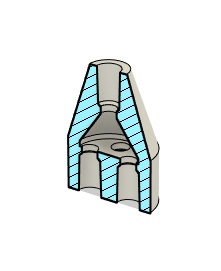

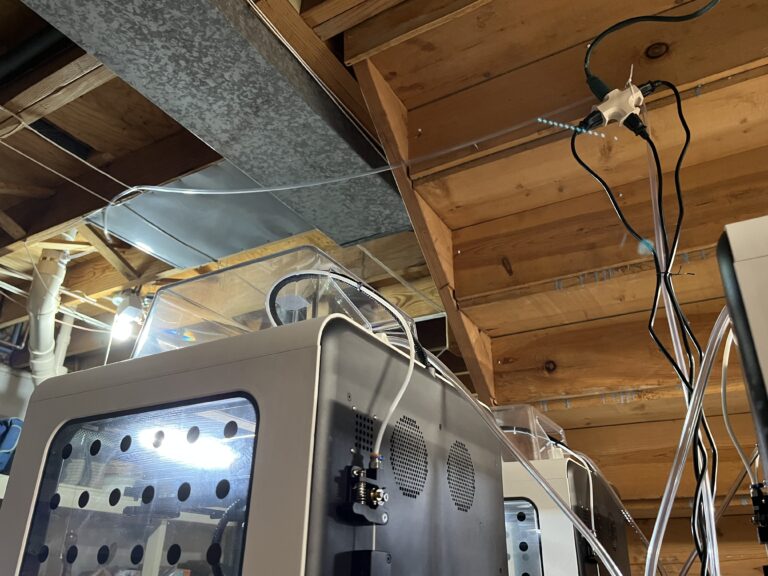

For our 3D printer farm, a single Sniffer pump is used to collect the fumes for (4) 3D printers simultaneously. A Sniffer pump moves approximately 45L/min of air volume, which translates to about 1.75 cuft/min. Each 3D printer enclosure is approximately 1 cuft., however, we don’t want the heated air in the enclosure to be constantly changed out, otherwise it would no longer be a heated enclosure. The first step was to design and print an air manifold to divide the vacuum air flow between the (4) machines and to allow a single Sniffer pump to be used. The manifold was located centrally and equal lengths of tubing routed to each printer. Super glue (cyanoacrylate) was used to secure and seal the tubing connection at the manifold ports.

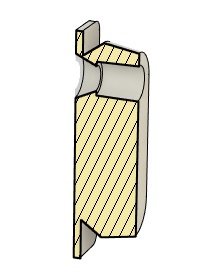

Since the goal is to capture just the fumes that are escaping the enclosure rather than to exchange the air, we needed to position the end of the tubing near the topmost opening of the enclosure where the heated air and fumes were naturally escaping. To do this, we designed and printed a slip-on tubing clip that engages an opening in the top cover where the Bowden tube enters the enclosure. This clip works pretty well with our printers and can easily be removed whenever the machine needs to be uncovered. For other printer models, a similar clip or magnetic holder to position the end of the tubing at the right spot will need to be designed and printed. Note that the air temperature at the collection point can be fairly warm but should not be hot.

Since our printer farm is currently located in the basement of a residential home we had easy access to existing sanitary pipes for air exhaust. We selected a nearby sanitary pipe located beneath a first floor bathroom for our air exhaust point. Air exhaust tubing was routed from the durability test pump located on the floor underneath our printer tables, up into the ceiling structure, and then across to the connection point.

To complete the install, we added a control signal cable extension to move the LED push button switch location to the top of the work table for easy access.

The STL and STEP files are linked below for reference and our 3D printers are Creality model CR-200B.

We are not certain how long our durability unit will continue to run for or if the Sniffer pump will be able to handle extended heat exposure as we increase our production volume, but so far the results have been excellent. We will continue to update this post with more data as it becomes available. Although the Potty Sniffer seems to work well for this application, we still aren’t able to endorse it for use in this manner at this time.

4-way air manifold: STL+STEP

Air intake tubing clip: STL+STEP