The Potty Sniffer system eliminates toilet odor by capturing it at the source before it has a chance to spread. Odor is drawn from the toilet bowl using existing toilet water flow passages, through a specially designed air intake shroud and vacuum pump, and exhausted into sanitary drainage pipes or directly outside. By capturing odor from a small, enclosed space, the amount of air needed to be removed is greatly reduced. This allows for a small “Sniffer” pump, tubing, and existing sanitary pipes to be used for venting odors instead of the high air flow ventilation fan and in-wall air ducts that are normally needed. This makes installation much simpler and allows for the system to be easily installed into existing bathrooms without needing to cut existing walls or install venting ducts.

Can You Really “Sniff” Away That Much Odor?

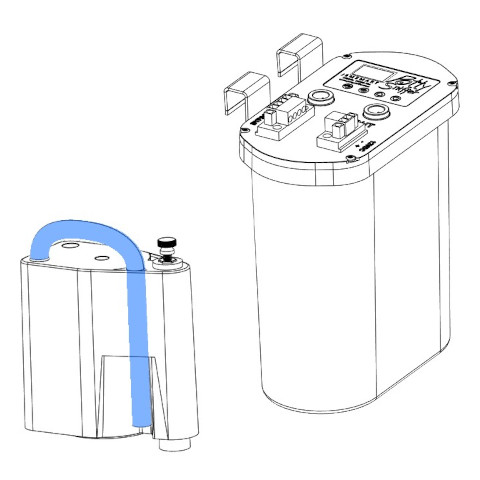

Sniffer Pump and Intake Shroud Design

The Potty Sniffer pump generates approximately 10PSI of air pressure allowing it to draw fumes in through the toilet bowl passages and exhausting it out through long tubing runs. The pump is also capable of surviving accidental water suction and has built in check valves to prevent the backflow of sewer gases through the exhaust line. The Sniffer pump includes a built-in run timer that automatically shuts off the pump after a desired run time and is user controlled using an illuminated LED push button that mounts on the outside of the toilet tank.

The specially designed intake shroud forms a vacuum chamber over the overflow pipe opening when sealed by the toilet tank water level at full fill, allowing the Sniffer pump to focus its suction on drawing odors from the bowl. When the toilet is flushed, an air vent is opened to break the vacuum seal preventing water from being sucked into the pump during the flush and refill cycle. A vacuum relief float valve provides additional protection in case the water level rises inside the intake shroud due to vacuum towards the end of the refill stage.

A Class II AC/DC power supply provides 12VDC power while protecting for short circuit or overload conditions. Powering the system with low voltage direct current electricity makes it safe to operate in wet environments. Low voltage (speaker) wire is used for the main power connection and can be of varying length to support different installation requirements.

Tubing and Exhaust Fittings

3/8″ OD flexible vinyl tubing is used for all intake and exhaust pump connections. This tubing, along with low voltage power and signal wiring, are small diameter and may be easily routed for through-wall and in-wall installation requirements.

Exhaust fittings for connections to existing plumbing pipes or through wall to the building exterior only require 3/8″ drill holes to complete. Tubing connections are made using 3/8″ push-to-connect ports under low pressure conditions for the Potty Sniffer system. These are normally rated for high pressure (120 PSI) applications so can be reliably used for air exhaust venting into sanitary plumbing.